Have you ever wondered how foam boards are manufactured? It's pretty interesting! These foam boards are created by a special machine- the foam board machine. This machine is very vital as it supports factories to prepare the foam boards in an easier and time-saving manner. This article will explore how foam board machine works and why it is so important.

Creating foam boards manually could be a taxing process and time consuming as well. It is energy draining and time-consuming work, especially when there are many boards to be made. Xinhe pvc foam board machine was created so as to help make this work less complicated and faster. This amazing machine allows factories to create foam boards faster, rather than doing everything by hand. This means that they are able to produce more foam boards in a lesser period of time. More foam boards can be made when the factories are able to churn them out, which in turn makes its customers happy as they receive their order quickly too. Also, this is making the factory more money by selling boards!

This machine allows manufacturers to make the foam board for less and easier than before without several employees cutting and forming it by hand at their factories. So far, less work and easier! When Xinhe pvc foam board making machine is being used to cut the foam boards it means they will be closer in size and shape. This is crucial in some products, because it guarantees that everything works like you expect.

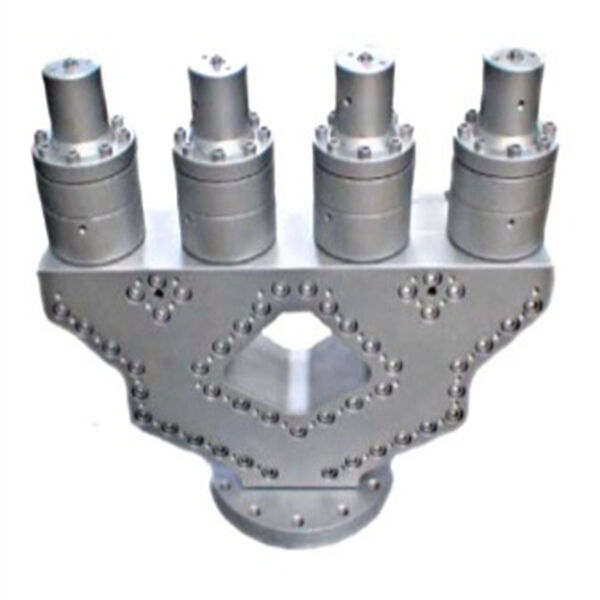

Foam board machine is a piece of machinery designed for manufacturing foam boards. The first, and special thing about Xinhe pvc foam board manufacturing machine is the material used to create a lightweight foam; a method of varying complexity commonly referred to as either foam extrusion or expansion. In the process, the foam is heated and reacted with chemicals. Then the foam is pushed through a die, which molds it to a specific shape. The die shapes the foam into an appropriate case dimension. The foam is permitted to cool after it passes through the die, which hardens and strengthens it. The process is designed to help guarantee that the foam boards are not only strong but versatile for a range of uses.

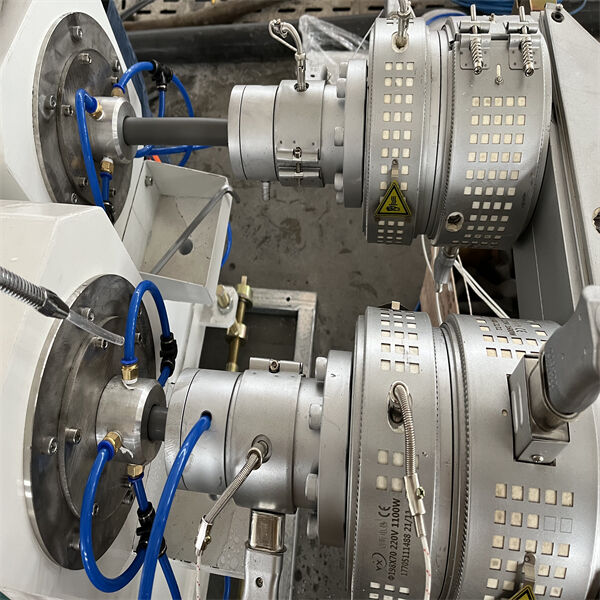

We pride in the fact that our foam board machines are among the best construction equipment available of its kind. For one, they are constructed out of durable materials that will endure years to come. In other words, manufacturers can rely on them to be effective for decades. Second, they are produced using modern machine-built tech. Being able to rely that this tech works lets factories trust it actually does the job. Our PVC Foam Board Production Line have a final condition that they are guaranteed. These provide a sense of security for customers, in that things are under warranty if something goes wrong.

Our foam board machines have the ability to produce great number of foam boards in less time. This means that they can take orders from more customers and maximize their earnings. This benefits businesses because factories can get more orders done in less time, so those foam boards will be shipped off instantly. Another thing is that pvc foam board machine can cut the foam boards themselves, which in turn lesser labor forces are needed to do so manually. This will reduce costs for the factory and allow them to spend that money on other things to help grow their business.

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of Foam board machine, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

We adhere to the strictest standards for Jiangsu Xinhe for machine steel thickness and materials We also offer an inventory of components that are vulnerable The Foam board machine we use are built to guarantee safety and have a long life expectancy as well as a low rate of failure and stable efficient production Many of our customers have utilized their machines for more than eight years

We can tailor the machine configuration according to the particular requirements of our customers Factory direct sales premium product quality and a comprehensive after-sales service Our machines have a lifespan of over Foam board machine and are highly regarded by clients from Vietnam Indonesia Saudi Arabia South Africa Bolivia and various other regions

Pre-Sales: Our sales team, with over 5 years of experience, can suggest the appropriate machine configuration for you. We provide 24 hour customer support and factory tours with video.In-Sales: We provide visual production, from raw steel up to finished products and total line production videos.After-Sales: Our engineers offer on-site service for a fee, and lifelong Foam board machine assistance from raw materials to final products.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy